BR British Rail Crimson & Cream

Crimson and Cream Crimson Cream Blood & Custard Blood Custard Blood and

Custard BR British Rail Crimson & Cream Crimson and Cream Crimson Cream

Blood & Custard Blood Custard Blood and Custard BR British Rail Crimson

& Cream Crimson and Cream Crimson Cream Blood & Custard Blood Custard

Blood and Custard

London,

Brighton & South Coast Railway

Crystal Palace ‘CP’

‘Elevated

Electric’ AC stock

|

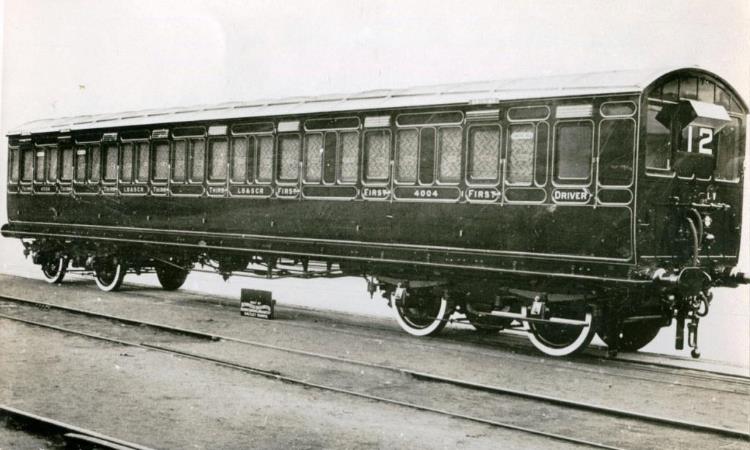

CP

stock Driving Trailer Composite car 4004 in 1911 as delivered in LBSCR umber

livery. In April 1925 it was renumbered 9828 and received lined olive green. Note

the different door vents (with label above) for the three smoking

compartments. Rebuilt

for 3 Car Motor Units in May 1929 with body (into unit no.1742 as TC 9742)

written off in the Dorking Collision on 22nd December 1941 being separated

from underframe (into unit no.1733 as TC 9725) scrapped at Newhaven in August

1959. |

Around the turn of the century, the London, Brighton & South

Coast Railway (LBSCR) were concerned about falling traffic receipts in the

suburban area and also wished to make economies in the costs of working their

system. So, they began investigations into the feasibility of working their

trains electrically. Electric operation of trains was now becoming quite

practical and was indeed already in operation on a number of railways abroad

and the LSWR had commenced limited electric operation in 1898 in the Waterloo

& City Railway tube line.

The construction of further electrified tube railways in London

and the parallel electrification of some competing tramway routes also spurred

these investigations by the LBSCR and the company obtained an Act of Parliament

in July 1903 to enable it to electrify parts of its system. Philip Dawson was

retained as a consulting electrical engineer to investigate the most suitable

system and from an early stage it was agreed that the system chosen should be

suitable for use on possible future extensions of the system beyond the suburban

area. Dawson took into account an earlier report to the LBSCR board presented

in 1902 by the Chief Engineer which pointed out a number of disadvantages of

the third rail system for the LBSCR network and presented a report to the board

in July 1904 recommending the adoption of a single‑phase alternating

current system at nominal 6,700 volts using overhead contact wire. The system

was envisaged as suitable for the whole suburban network and with the

possibility of later extensions should this be required.

Dawson was instructed to prepare plans for electrification of

the lines between Battersea Park and Peckham Rye via the South London line and

contracts were let in April 1905, awarded to the Allgemeine Elektricitats-Gesellschaft

(AEG) of Berlin; this company sub‑contracting the overhead line work to

Messrs R. W. Blackwell & Company of London, who in turn sub-contracted

further with British Thomson‑Houston Co providing switchgear and Johnson

& Philips also Siemens Bros providing cabling. Soon after these contracts

were let, the LBSCR decided to extend the electrification scheme from Peckham

Rye into London Bridge and from Battersea Park into Victoria so that the whole

South London line route was covered, and further contracts were let to cover

these extensions in March 1906. The rolling stock provision for the line was

awarded to the Metropolitan Amalgamated Carriage & Wagon Company of

Birmingham.

|

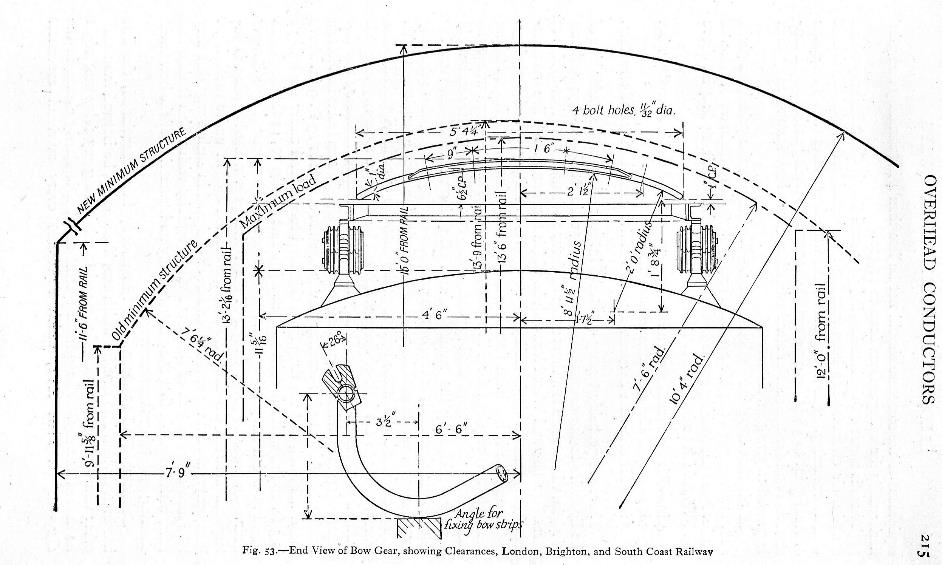

Bow Gear Clearances Diagram shewing the clearances for the train’s AC Bow

Collectors. |

The Overhead

Power for the system was obtained from the London Electric

Supply Corporation's generating station at Deptford and supplied at nominal

6,700 volts, 25 hertz via cables direct to a switch room at Queens Road,

Peckham and a distribution room at Peckham Rye. Power was then distributed via

lineside cables to switch cabins located at each station which supplied the

overhead equipment. Wherever possible the current supply arrangements allowed

one line to be isolated without having to isolate the adjacent track. The

overhead lines were suspended at a contact height of 16' above rail level,

though this was reduced under certain low bridges to 13' 9" (where

there were ‘Dead’ sections) whilst in the vicinity of the platforms at Victoria

and London Bridge the height was raised to 19' 9" to give greater

clearances as staff still had to go onto carriage roofs to lamp oil lit stock

or light gas lamps in some gas lit stock.

The contact wire was suspended from two catenaries; these being

located one to each side and away from the centre line of the track to avoid

damage to the insulators from the blast of locomotive chimneys. The catenaries

were made of 12 strand galvanised steel and the droppers from these to the

contact wire were formed as a stiff ‘V’ shape and were clipped to the contact

wire by phosphor bronze clips. Droppers were spaced every 10' and held the

copper contact wire off centre above the track with alternate deviations of

9" from the track centre line; this zig-zagging of the contact wire was

designed to prevent the wire wearing a groove into the bow collectors of the

trains.

The structures supporting the catenaries were mostly steel

lattice gantries, the catenaries passing above these structures and supported

on porcelain insulators, though there were some variations in the vicinity of

overbridges. The overhead gantries were usually spaced about 150' apart, though

some gaps were as small as 50' and the longest was 210' owing to siting

difficulties.

Minimum clearance around the contact wire was specified at 3",

though 4" was normally allowed, and the loading gauge height of the LBSCR

was set at 13' 6" so the minimum height of the contact wire had to be

set at 13' 9". As a consequence, there was a need for ‘Dead’ sections

with the wire at this height under five overbridges on the electrified lines.

Crystal

Palace Extension

The almost immediate success of the South London line

electrification scheme which commenced from 1st December 1909

in raising passenger numbers on this line, led to the LBSCR board to quickly

authorise the extension of electric working early in 1910. It was then planned

to electrify the lines from Victoria to Crystal Palace via Clapham Jct. and Balham.

The same main contractors who had been used for the South London scheme were

again contracted for this scheme.

Electrification work commenced at Battersea Park (junction for

the South London line) and only the two Local lines were electrified as far as

the south end of Clapham Jct. station, then all four lines were equipped to the

junction at Balham to allow an overtaking facility if required. The double

track through Streatham Hill to the junction at Crystal Palace were equipped

and the overheads were then taken into the London Bridge platforms at Crystal

Palace and just beyond the station to allow trains to reverse into the centre

sidings.

One of the sidings at Pigs Hill (Clapham Jct.) was electrified

to enable trains to be reversed there from the south whilst the Up Bay platform

was also equipped at Streatham Hill to enable trains from Victoria to reverse

there if required. Two of the sidings on the down side were also electrified

here for stock berthing.

Selhurst Maintenance Depot

Whilst this scheme was still in the planning stage, it was

decided to extend the electrification still further. The nearest suitable site

to the route for the building of a maintenance depot and berthing sidings was

identified between Norwood Junction and Selhurst stations and a carriage shed

and berthing sidings were laid out here with access from both the Norwood Jct.

and Selhurst ends. To gain access to these facilities, electrification was then

planned to be extended from the junction at Crystal Palace to Norwood Jct. and round

the spur to Selhurst.

Wires were carried beyond Selhurst towards Thornton Heath to

allow terminating trains to reverse back into the depot. The ‘Croydon’ bay

platforms along with the Up Siding at Crystal Palace were also included. The

line from Peckham Rye via Tulse Hill was also

included, with electrification being taken around both the spur lines up to the

junctions with the Crystal Palace line at Leigham

Junction and West Norwood Junction.

Part of the new maintenance depot was built upon the former Selhurst

cycle-racing track to the east of Selhurst Road and the London to Croydon

Railway Line.

|

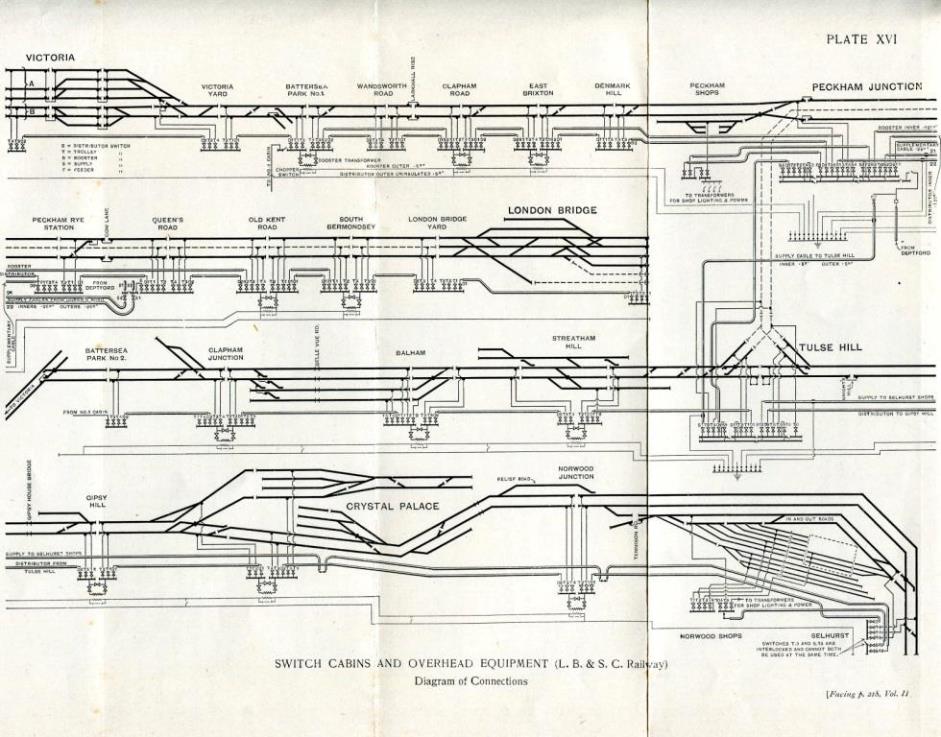

Switch Cabins & Overhead Equipment Diagram Victoria

station’s platforms 9 to 13 were electrified and at London Bridge the scheme

additionally electrified platforms 16 & 17; platforms 19 to 22 already

having been electrified under the South London ‘AC’ scheme. In

those days Peckham Rye, Queens Road, Old Kent Road & Hatcham (closed 1st

January 1917 never to reopen – possibly the first electrified mainline station

to close) and South Bermondsey all had side platforms. Note

electrification of the line up from Tulse Hill to

Peckham Rye along with the centre road

through to London Bridge Yard thence into London Bridge Station. At

Clapham Junction there was a turn-back facility in platform 18 & 19 (inc.

Pigs Hill) thence four-track electrification to Balham. The Down Siding at

Gipsy Hill was also electrified. There

was extensive electrification at Crystal Palace including on the Sydenham

line to permit access to the centre sidings between platforms 3 & 4. Into

Norwood Junction the Relief Road was electrified. Selhurst

depot had ten roads electrified and even today roads 7 to 10 are still called

the ‘AC sidings’. This electrification scheme

terminated just beyond Selhurst station to allow reversals into the

depot. |

Overhead Line Extensions

Overhead equipment for these extensions was similar to that used

on the South London lines, though of slightly lighter construction. However,

there was a greater variety of supporting structures owing to various lineside

constraints. In the tunnels at Leigham Court

(Streatham Hill), Crystal Palace and Knights Hill (Tulse

Hill) steel beams were let into the tunnel crowns and the insulators placed on

these. Some section where the track was single (the spurs between Norwood Jct.

and Bromley Jct.) used a simple pole and arm support.

Between Pouparts Jct. and Clapham Jct.

it was not possible to find space for overhead supports between the LBSCR Main

lines and the LSWR Local lines so this section had supports cantilevered out

from uprights alongside the LBSCR Down Local line. These supports were extended

across all four LBSCR tracks so that future wiring of the Main lines could be

carried out easily if required. Sufficient space was left between the uprights

of these gantries to allow a possible fifth road to be laid through them if

widening of the section became necessary.

The centre line between Peckham Rye and London Bridge was also

electrified as part of this scheme along with two further platforms at London

Bridge (16 & 17). Power supply for these lines was again taken from the

Deptford generating station of the London Electric Supply Corporation and large

distribution cabins were built at both Peckham Rye and Tulse

Hill. The switch cabins were spaced at greater distances than those on the

original South London scheme.

Electric Services

Work on these extensions proceeded quickly and the line from

Victoria to Crystal Palace via Streatham Hill was first worked electrically on

12th May 1911, this being the first day of a Festival of Empire

exhibition at Crystal Palace. Services between Peckham Rye and Streatham

Hill/West Norwood were planned to commence from 1st June 1912,

the delay being due to the electricity supply company having to install more

generating capacity to cope with the increased demand, however electric trains

actually commenced from 1st March 1912 owing to a coal shortage

following a miners strike, with the full service

commencing in June.

Initial weekday train services over the new lines consisted of a

twenty-minute frequency from Victoria to Crystal Palace from 7am to 8am, then

stepping-up to ¼ hourly until 4pm, five trains per hour until 6pm, reverting to

¼ hourly until 9pm and every 20 minutes until the last train at midnight.

When the lines via Tulse Hill opened,

a ¼ hourly service operated from London Bridge to Crystal Palace from 9am to

11am, then reducing to every 20 minutes until the last at 11 55pm. A service

from London Bridge to Victoria via Streatham Hill operated every 20 minutes

until 9 40am, then reducing to hourly until about 4pm when the 20-minute

frequency resumed until 8 8pm when the trains went back to about hourly. During

the middle part of the day some of the hourly London Bridge to Victoria trains

terminated at either Streatham Hill or Clapham Jct.

‘CP’ Rolling

Stock

Rolling stock for the new services was again contracted to the

Metropolitan Amalgamated Carriage & Wagon Co Ltd (MAC&W) of Birmingham.

Thirty new three-coach trains were needed for the service and therefore thirty

motor brake thirds and thirty driving trailer composites were ordered from

MAC&W whilst Lancing works was instructed to build a further twenty-six

driving trailer composites. Owing to some tight clearances in Crystal Palace

tunnel, the overall dimensions of these vehicles was restricted to bodies

8' 0" wide and 54' 0" long.

These coaches were built much more to LBSCR standards than the

South London line stock, all accommodation being in compartments (no side

corridors). Experience gained with the South London stock led to these trains

being more flexible in operation, all vehicles having a driving cab at one end.

There were fewer driving trailers than needed to make-up thirty complete

trains, so formations constantly varied as more motor coaches were out of

traffic for maintenance than trailer coaches.

All coaches were built on 54' underframes with bogie centres at

37', those of the motor coaches having the same style of heavy side girders as

the SL units, whilst trailers had much lighter truss rods. All coaches were

fitted with conventional buffers and screw couplings at each end. Bodies again

had aluminium sheeting covering the roofs, sides and ends as a precaution

against stray currents from the overhead equipment.

Bodysides had wooden beading dividing the panelling with two

horizontal bands beneath the window line. Within this area, the vehicle

numbers, compartment class (in words) and LBSCR lettering was displayed in gold

letters. The vehicles were all painted in umber brown with yellow & black

lining picking out the panelling.

Cab ends were quite plain, basically being a standard coach end

with two large observation windows added. They had a similar arrangement to the

SL units with an electric white light which could be covered by a red glass on

a pivoting horizontal rod to provide head and tail indications. Between the cab

windows a headcode panel was fitted into which an enamel plate displaying the

required headcode could be clipped. These were illuminated from above by

electric lamps hidden under a sloping hood. A whistle was fitted on the

nearside of the driver's window.

Similar air hose connections to the SL stock were placed low

down on the cab front close to the drawhook, three

hoses for train pipe, main reservoir pipe & bow air systems. Jumper sockets

were placed on the headstock, loose jumpers being used to connect these to adjacent vehicles when the cab was marshalled

intermediately within a train.

Bodysides had a doorway into each compartment with the usual

droplight within it, each compartment also having two ¼ light windows, one each

side of the door. Each door had a ventilator above the droplight, those in

smoking compartments having the vents at each end whilst those in non-smoking

compartments had the vent along the lower edge. Internally the compartments

were less ornate than those of the SL stock but still quite comfortable. First-class

had a blue cloth upholstery whilst thirds had a red/black repp

material. First-class seated four aside whilst thirds seated five aside. Each

compartment had two electric lamps, and there were advert frames placed above

the seats and below the luggage racks. Some compartments later had enamel

adverts fixed to the inside of the doors below the droplights.

Overall, each CP 3-car train seated 48 first and 170 third and

weighed 99 tons 6 cwt and was 172' 9" long.

Motor Coaches

Motor coaches consisted of a cab and brakevan

area 11' 6" long, this having a double opening door on each side, the

driver using these doors. Forward of these doors at the end of the bodyside

there was a droplight window, the same size as those of normal doorway ones,

though not fitted within a door, this for use of the driver. The driver

operated from a cubicle in the front nearside corner of the brakevan

area and there was an HT equipment cupboard below the offside observation

window.

Beyond the brakevan area there were 7

third class compartments, each 5' 11" wide. The roof was again

flattened above the brakevan and partly over the

first passenger compartment to allow space for the bow collectors to be mounted

above. Equipment below the underframes was very similar to that on the SL units

although at 150hp the motors were more powerful; these again being from Winter‑Eichberg. These coaches were 57' 7" long over buffers

and weighed 51 tons 6 cwt and seated 70 third. Their LBSCR diagram

number was 282.

Driving Trailer Composites

Driving trailer composites consisted of a small driver's cab

4' 0½" wide, entered from either side via a standard door with

droplight, there being no other side window to the cab. Behind this were three

first class compartments 6' 6¾" wide and five third class

compartments each 5' 10¼" wide. They weighed 24 tons and seated

24 first and 50 third. Their LBSCR diagram number was 283.

Train Formations

When first introduced the trains were formed with the motor

coach at one end of two trailers, but operating experience soon saw this

altered to having the motor coach in the centre with a driving trailer on each

end. Many peak hour trains were made up to six coaches using two 3-car

formations, and a few later ran as eight coaches with a six-car train having a

further motor coach and trailer added to one end. These trains were maintained

at the new Selhurst depot with some heavier work undertaken at Peckham Rye

repair shops. Body overhauls were carried out at Lancing works.

Further coaches of both types were added to the fleet quite

quickly (possibly as a result of the late alteration of plans to extend the

electrification scheme) and a further four motor coaches and four trailers were

constructed during 1912 by Metropolitan Carriage, Wagon & Finance Co. Ltd

(the new name for the original builders) again at Saltley.

Lancing Works built a further eight driving trailer composites (in two batches

of four with the first delivered by June 1913, the second delivered by the end

of 1913). Operation of the new trains was a success and traffic quickly grew by

as much as 70%.

The LBSCR provided ‘Stopping Marks’ on white enamel plates with

blue figures showing 2, 3, 5, 6 etc. as appropriate to indicate to drivers

where to pull-up at each station, and ‘Coasting Marks’ consisting of a blue

plate with a white cross were located (usually on an overhead support) on the

approach to stations to show when power should be shut off and the train

allowed to coast. These arrangements were also spread to the South London line.

War Years

During the First World War the electrified services suffered

some curtailments, the Sunday trains from London Bridge to Crystal Palace being

withdrawn and North Dulwich station closed on that day. Service patterns were

adjusted and although basic frequencies remained unchanged the services did not

run to a ‘clockface’ regular interval pattern.

The onset of war also stopped progress with the next phase of

the LBSCR's extension of electrification which included the lines from London

Bridge to Norwood Jct. via Forest Hill and the Sydenham Spur to Crystal Palace,

the lines from Balham to Cheam via both Mitcham Jct. and Norbury and the lines

from Selhurst /Norwood Jct. to Coulsdon North.

However, a number of driving trailer vehicles for use on these

lines had been authorised for construction at Lancing and work on these had

commenced. These were very similar to those produced for the CP stock, the

difference being that they included four first and four third class

compartments. Two of these coaches were therefore allocated to the CP fleet,

these coaches seating 32 first and 40 third, altering the capacity of any unit

in which they were formed to 56 first and 160 third.

Southern Railway

After the war, much of the further extension of the

electrification scheme was implemented by the Southern Railway though it only

had a short life as the SR had very early on decided to standardise on the ‘750v’

DC Third Rail system of electrification.

These extensions (the Coulsdon & Wallington scheme)

completed the final expansion of the LBSCR's overhead system and the extra

stock allocated to work it became known as the CW (Coulsdon & Wallington)

stock. The two CW driving trailers earlier allocated to the CP fleet however

remained working on these routes. Once the extensions had been completed (in

1925) some of the CP stock could be found working further afield, they

certainly worked to East Croydon, though they remained basically on their

original services.

From 1924, the CP fleet was renumbered into a new series by the

SR as vehicles were overhauled at Lancing works. At this time, they were also

repainted green and the new livery also changed the location of the coach

numbers, now being placed much higher up the bodyside, and figures appeared on

the lower panels of the doors to denote the class designation of that

compartment. However, not all vehicles were dealt with before the CP fleet

began to be withdrawn, this taking place during the latter part of 1928 and all

were out of service by mid-1929, as their routes were converted to DC

operation.

Conversion of ‘CP’ stock to DC Operation

All the coaches were then stripped of various items of AC

equipment at Peckham Rye and then reused in various ways as part of the

expanding fleet of DC electric units.

The motor brake thirds were converted at Lancing into trailer

thirds. The bodies remained on their original girder trussed underframes, the

former cab and brakevan area being removed and

replaced with two further third-class compartments, making these vehicles into

54' long 9-compartment coaches and they were used in trailer units 1168 ‑ 1187.

The driving trailer composites were converted in three different

ways, 14 of them becoming motor brake composites, this involving a new cab and brakevan being added to the former third-class end of the

coach, one of the original third-class compartments being replaced during this

alteration. The former cab at the other end was removed. In this form they then

had four third and three first compartments.

Conversion work took place at both Ashford and Eastleigh and the

altered bodies were removed from their 54' underframes and these were then

lengthened to 62' 0" and the bodies replaced on them, though they did

not go back onto their original frame, seven going onto new Lancing built

underframes. These new motor coaches were then formed into units 1717 ‑ 1727

and 1737 ‑ 1739.

A further two driving trailer composites were altered to 54'

trailer thirds at Lancing with little alteration to the bodies other than

downgrading the former first-class compartments to third and converting the

former cab into a coupe compartment seating 5. These 8½ compartment coaches

were then formed into trailer units 1182 and 1183.

The remaining 52 driving trailer composites were rebuilt as

62' 0" trailer composites, again the work was split between Ashford

and Eastleigh. Bodies were removed from their underframes which were then

lengthened to 62' 0” and the rebuilt bodies replaced onto them, again not

onto their original frames. Body alterations involved replacing the original

cab with a further first-class compartment and the addition of a further third-class

compartment at the other end. In this form they now had four first and six

third compartments and were included in new DC units 1717 ‑ 1768.

The two odd CW driving trailer composites used as part of the CP

fleet since 1914 were altered as 54' long trailer thirds with the former cab

being converted into a coupe compartment seating 5 and the four first class

compartments downgraded to third. These two coaches were then included in

trailer units 1184 and 1185, conversion work took place at Lancing.

The following lists show details of the CP fleet, with coaches

listed in their original number order. Details of builder, new date and

subsequent SR ‘AC’ number with date of renumbering (where appropriate) are

shown along with the date of conversion to ‘DC’, the works responsible for the

conversion, their new numbers, new unit and type of vehicle conversion. Nearly

all the DTCs had their bodies split from the underframes whilst the frames were

lengthened, they did not go back onto their original frames and the new number

of the body is shown above the number of the vehicle that the underframe was

used under. The ‘new’ date of coaches is as reported by the LBSCR accounting

system which recorded half-yearly (June & December); the actual build dates

would have been more spread.

|

CP Motor Brake Thirds |

|||||||||

|

Coach No. |

Built |

Date |

SR ‘AC’ No. |

Date Renum. |

Date Rebuilt |

Works |

SR ‘DC’ No. |

Unit |

Type |

|

3231 |

MACW |

1911 |

8567 |

Jul-24 |

Jul-30 |

LANC |

9294 |

1187 |

TT |

|

3232 |

MACW |

1911 |

8568 |

Sep-26 |

Aug-29 |

LANC |

9265 |

1172 |

TT |

|

3233 |

MACW |

1911 |

8569 |

Dec-25 |

Jan-30 |

LANC |

9280 |

1180 |

TT |

|

3234 |

MACW |

1911 |

8570 |

May-26 |

Aug-29 |

LANC |

9267 |

1173 |

TT |

|

3235 |

MACW |

1911 |

8571 |

Jan-28 |

Mar-30 |

LANC |

9291 |

1185 |

TT |

|

3236 |

MACW |

1911 |

8572 |

Jan-27 |

Jul-29 |

LANC |

9259 |

1169 |

TT |

|

3237 |

MACW |

1911 |

8573 |

Dec-24 |

Jul-29 |

LANC |

9262 |

1171 |

TT |

|

3238 |

MACW |

1911 |

8574 |

Mar-25 |

Jul-30 |

LANC |

9295 |

1187 |

TT |

|

3239 |

MACW |

1911 |

8475 |

Mar-27 |

Aug-29 |

LANC |

9269 |

1174 |

TT |

|

3240 |

MACW |

1911 |

8476 |

Sep-26 |

Sep-29 |

LANC |

9275 |

1177 |

TT |

|

3241 |

MACW |

1911 |

8477 |

Dec-24 |

Aug-29 |

LANC |

9271 |

1175 |

TT |

|

3242 |

MACW |

1911 |

8478 |

May-24 |

Feb-30 |

LANC |

9287 |

1183 |

TT |

|

3243 |

MACW |

1911 |

8579 |

Dec-25 |

Jan-30 |

LANC |

9278 |

1179 |

TT |

|

3244 |

MACW |

1911 |

8580 |

May-26 |

Jul-29 |

LANC |

9260 |

1170 |

TT |

|

3245 |

MACW |

1911 |

8581 |

Jun-27 |

Jul-29 |

LANC |

9263 |

1171 |

TT |

|

3246 |

MACW |

1911 |

(8582) |

- |

Jul-29 |

LANC |

9256 |

1168 |

TT |

|

3247 |

MACW |

1911 |

8583 |

Sep-25 |

Feb-30 |

LANC |

9285 |

1182 |

TT |

|

3248 |

MACW |

1911 |

8584 |

Jun-27 |

Aug-29 |

LANC |

9266 |

1173 |

TT |

|

3240 |

MACW |

1911 |

8585 |

Sep-27 |

Jul-29 |

LANC |

9261 |

1170 |

TT |

|

3250 |

MACW |

1911 |

8586 |

Oct-24 |

Sep-29 |

LANC |

9272 |

1176 |

TT |

|

3251 |

MACW |

1911 |

8587 |

Sep-27 |

Feb-30 |

LANC |

9289 |

1184 |

TT |

|

3252 |

MACW |

1911 |

8588 |

May-24 |

Aug-29 |

LANC |

9270 |

1175 |

TT |

|

3253 |

MACW |

1911 |

8589 |

Oct-24 |

Sep-29 |

LANC |

9273 |

1176 |

TT |

|

3254 |

MACW |

1911 |

8590 |

Jan-27 |

Sep-29 |

LANC |

9276 |

1178 |

TT |

|

3255 |

MACW |

1911 |

8591 |

Jun-25 |

Sep-29 |

LANC |

9277 |

1178 |

TT |

|

3256 |

MACW |

1911 |

8592 |

Jan-24 |

Aug-29 |

LANC |

9268 |

1174 |

TT |

|

3257 |

MACW |

1911 |

8593 |

Jun-25 |

Aug-29 |

LANC |

9264 |

1172 |

TT |

|

3258 |

MACW |

1911 |

8594 |

Oct-25 |

Jul-29 |

LANC |

9258 |

1169 |

TT |

|

3259 |

MACW |

1911 |

8595 |

Jul-24 |

Sep-29 |

LANC |

9274 |

1177 |

TT |

|

3260 |

MACW |

1911 |

(8596) |

- |

Jan-30 |

LANC |

9281 |

1180 |

TT |

|

3261 |

MCWF |

1912 |

8597 |

Apr-27 |

Jul-29 |

LANC |

9257 |

1168 |

TT |

|

3262 |

MCWF |

1912 |

8598 |

Jan-24 |

Jan-30 |

LANC |

9279 |

1179 |

TT |

|

3263 |

MCWF |

1912 |

8599 |

Jan-28 |

Feb-30 |

LANC |

9283 |

1181 |

TT |

|

3264 |

MCWF |

1912 |

8600 |

Mar-25 |

Mar-30 |

LANC |

9293 |

1186 |

TT |

|

CP Driving Trailer Composites |

|||||||||

|

Coach No. |

Built |

Date |

SR ‘AC’ No. |

Date Renum. |

Date Rebuilt |

Works |

SR ‘DC’ No. |

Unit |

Type |

|

4001 |

MACW |

Jun-11 |

9825 |

Sep-25 |

Aug-29 |

ELGH |

9749 |

1749 |

TC |

|

4002 |

MACW |

Jun-11 |

9826 |

Sep-25 |

Jul-29 |

AFD |

9732 |

1732 |

TC |

|

4003 |

MACW |

Jun-11 |

9827 |

Feb-25 |

22-Mar-30 |

AFD |

9476 |

1765 |

TC |

|

4004 |

MACW |

Jun-11 |

9828 |

Apr-25 |

Jun-29 |

ELGH |

9742 |

1742 |

TC |

|

4005 |

MACW |

1911 |

9829 |

Sep-26 |

Jun-29 |

ELGH |

8874 |

1739 |

MBC |

|

4006 |

MACW |

Jun-11 |

9830 |

May-24 |

Jan-29 |

AFD |

9719 |

1719 |

TC |

|

4007 |

MACW |

Jun-11 |

9831 |

Jul-24 |

Feb-30 |

AFD |

9468 |

1757 |

TC |

|

4008 |

MACW |

Jun-11 |

9832 |

Jan-24 |

Jan-29 |

AFD |

9717 |

1717 |

TC |

|

4009 |

MACW |

Jun-11 |

9833 |

Oct-25 |

Jun-29 |

AFD |

9726 |

1726 |

TC |

|

4010 |

MACW |

Jun-11 |

9834 |

Jun-27 |

Sep=29 |

AFD |

9730 |

1730 |

TC |

|

4011 |

MACW |

Jun-11 |

9835 |

Jan-24 |

Feb-29 |

AFD |

9720 |

1720 |

TC |

|

4012 |

MACW |

1911 |

9836 |

Sep-26 |

Jun-29 |

ELGH |

8873 |

1738 |

MBC |

|

4013 |

MACW |

Jun-11 |

9837 |

Sep-26 |

May-29 |

AFD |

8598 |

1724 |

MBC |

|

4014 |

MACW |

Jun-11 |

9838 |

Feb-24 |

1-Jan-30 |

AFD |

9462 |

1751 |

TC |

|

4015 |

MACW |

Jun-11 |

9839 |

Sep-26 |

Jun-29 |

ELGH |

9738 |

1738 |

TC |

|

4016 |

MACW |

Jun-11 |

9840 |

Jun-27 |

5-Apr-30 |

AFD |

9478 |

1767 |

TC |

|

4017 |

MACW |

1911 |

9841 |

Apr-27 |

Feb-30 |

LANC |

9284 |

1182 |

TT |

|

4018 |

MACW |

Jun-11 |

9842 |

Mar-25 |

May-29 |

AFD |

9725 |

1725 |

TC |

|

4019 |

MACW |

Jun-11 |

9843 |

Sep-24 |

Aug-29 |

AFD |

9736 |

1736 |

TC |

|

4020 |

MACW |

Jun-11 |

9844 |

Dec-24 |

Feb-30 |

AFD |

9463 |

1752 |

TC |

|

4021 |

MACW |

Jun-11 |

9845 |

Sep-27 |

Jun-29 |

AFD |

9737 |

1737 |

TC |

|

4022 |

MACW |

Jun-11 |

(9846) |

- |

Feb-29 |

AFD |

8856 |

1721 |

MBC |

|

4023 |

MACW |

1911 |

9847 |

Apr-27 |

Jun-29 |

AFD |

8862 |

1727 |

MBC |

|

4024 |

MACW |

Jun-11 |

9848 |

Jun-27 |

May-29 |

AFD |

9724 |

1724 |

TC |

|

4025 |

MACW |

1911 |

9849 |

Oct-27 |

Jun-29 |

AFD |

8861 |

1726 |

MBC |

|

4026 |

MACW |

Jun-11 |

9850 |

Sep-27 |

Jul-29 |

ELGH |

9743 |

1743 |

TC |

|

4027 |

MACW |

Jun-11 |

9851 |

Oct-27 |

Jun-29 |

AFD |

9727 |

1727 |

TC |

|

4028 |

MACW |

Jun-11 |

9852 |

Jan-28 |

Feb-30 |

AFD |

9470 |

1759 |

TC |

|

4029 |

MACW |

Jun-11 |

9853 |

Apr-26 |

Jun-29 |

AFD |

9728 |

1728 |

TC |

|

4030 |

MACW |

Jun-11 |

9854 |

Jan-24 |

Feb-29 |

AFD |

8854 |

1719 |

MBC |

|

4032 |

LANC |

Jun-11 |

9855 |

Dec-25 |

Aug-29 |

AFD |

9734 |

1734 |

TC |

|

4032 |

LANC |

1911 |

9856 |

Jun-Jan-28 |

Feb-30 |

LANC |

9286 |

1183 |

TT |

|

4033 |

LANC |

Jun-11 |

9857 |

Jan-27 |

May-29 |

AFD |

8860 |

1725 |

MBC |

|

4034 |

LANC |

Jun-11 |

(9858) |

- |

Feb-29 |

AFD |

9721 |

1721 |

TC |

|

4035 |

LANC |

Jun-11 |

9859 |

Jan-28 |

1-Jan-30 |

AFD |

9467 |

1756 |

TC |

|

4036 |

LANC |

Jun-11 |

9860 |

Jan-24 |

Jan-29 |

AFD |

8853 |

1718 |

MBC |

|

4037 |

LANC |

Jun-11 |

9861 |

Feb-25 |

Jun-29 |

AFD |

9729 |

1729 |

TC |

|

4038 |

LANC |

Jun-11 |

9862 |

Jul-24 |

Feb-30 |

AFD |

9469 |

1758 |

TC |

|

4039 |

LANC |

Jun-11 |

9863 |

Jan-27 |

1-Jan-30 |

AFD |

9461 |

1750 |

TC |

|

4040 |

LANC |

Jun-11 |

9864 |

Dec-24 |

1-Jan-30 |

AFD |

9466 |

1755 |

TC |

|

4041 |

LANC |

Jun-11 |

9865 |

Jan-24 |

Feb-29 |

AFD |

9723 |

1723 |

TC |

|

4042 |

LANC |

Jun-11 |

9866 |

Feb-25 |

Sep-29 |

AFD |

9731 |

1731 |

TC |

|

4043 |

LANC |

Jun-11 |

9867 |

Jul-24 |

Jun-29 |

ELGH |

9741 |

1741 |

TC |

|

4044 |

LANC |

Jun-11 |

9868 |

Dec-24 |

Feb-30 |

AFD |

9464 |

1753 |

TC |

|

4045 |

LANC |

Jun-11 |

9869 |

Sep-25 |

1-Jan-30 |

AFD |

9465 |

1754 |

TC |

|

4046 |

LANC |

Jun-11 |

9870 |

Jun-27 |

Mar-30 |

AFD |

9473 |

1762 |

TC |

|

4047 |

LANC |

Jun-11 |

9871 |

Jun-25 |

Aug-29 |

ELGH |

9747 |

1747 |

TC |

|

4048 |

LANC |

Jun-11 |

9872 |

May-24 |

Jan-29 |

AFD |

9718 |

1718 |

TC |

|

4049 |

LANC |

Jun-11 |

9873 |

Jun-25 |

12-Apr-30 |

AFD |

9479 |

1768 |

TC |

|

4050 |

LANC |

1911 |

9874 |

Jan-24 |

Feb-29 |

AFD |

8855 |

1720 |

MBC |

|

4051 |

LANC |

Jun-11 |

9875 |

Jan-27 |

Mar-30 |

AFD |

9474 |

1763 |

TC |

|

4052 |

LANC |

Jun-11 |

9876 |

Jun-25 |

29-Mar-30 |

AFD |

9477 |

1766 |

TC |

|

4053 |

LANC |

Jun-11 |

9877 |

Apr-26 |

Aug-29 |

ELGH |

9748 |

1748 |

TC |

|

4055 |

LANC |

Jun-11 |

9878 |

Jan-27 |

Jul-29 |

AFD |

9733 |

1733 |

TC |

|

4056 |

LANC |

Jun-11 |

(9879) |

- |

Feb-29 |

AFD |

9722 |

1722 |

TC |

|

4057 |

LANC |

Jun-11 |

(9880) |

- |

Feb-29 |

AFD |

8858 |

1723 |

MBC |

|

4061 |

MCWF |

1912 |

9881 |

Oct-24 |

Jun-29 |

ELGH |

8872 |

1737 |

MBC |

|

4062 |

MCWF |

Dec-12 |

9882 |

Jul-24 |

Aug-29 |

AFD |

9735 |

1735 |

TC |

|

4063 |

MCWF |

Dec-12 |

9883 |

May-24 |

Feb-29 |

AFD |

8857 |

1722 |

MBC |

|

4064 |

MCWF |

Dec-12 |

9884 |

Oct-24 |

Jun-29 |

ELGH |

9739 |

1739 |

TC |

|

4065 |

LANC |

Jun-13 |

9885 |

Jan-26 |

Feb-30 |

AFD |

9471 |

1760 |

TC |

|

4066 |

LANC |

Jun-13 |

9886 |

Dec-25 |

Feb-30 |

AFD |

9472 |

1761 |

TC |

|

4067 |

LANC |

Jun-13 |

9887 |

May-26 |

Jul-29 |

ELGH |

9744 |

1744 |

TC |

|

4068 |

LANC |

Jun-13 |

9888 |

Oct-25 |

15-Mar-30 |

AFD |

9475 |

1764 |

TC |

|

4069 |

LANC |

Dec-13 |

9889 |

Dec-25 |

Aug-29 |

ELGH |

9746 |

1746 |

TC |

|

4070 |

LANC |

Dec-13 |

9890 |

Jan-28 |

Aug-29 |

ELGH |

9745 |

1745 |

TC |

|

4071 |

LANC |

Dec-13 |

9891 |

Apr-26 |

Jun-29 |

ELGH |

9740 |

1740 |

TC |

|

4072 |

LANC |

Dec-13 |

9892 |

May-24 |

Jan-29 |

AFD |

8852 |

1717 |

MBC |

|

CP Driving Trailer Composites |

|||||||||

|

Coach No. |

Built |

Date |

SR ‘AC’ No. |

Date Renum. |

Date Rebuilt |

Works |

SR ‘DC’ No. |

Unit |

Type |

|

4084 |

LANC |

1914 |

9893 |

Apr-27 |

Feb-30 |

LANC |

9288 |

1184 |

TT |

|

4085 |

LANC |

1914 |

9894 |

Apr-27 |

Feb-30 |

LANC |

9290 |

1185 |

TT |

|

Thanks go to research

author John Atkinson, webpage author, editorial and additional information from

C.Watts along with the many photographers listed

below their images. |

|

In memory of J.F. Watts

and his childhood recollections of the ‘CP’ rolling stock “hissing through

Crystal Palace with their great big bow-collectors”. |

ALL TEXT AND PHOTOGRAPHS

ARE COPYRIGHT